When it comes to vertical transportation in modern buildings, choosing the right elevator system is more than just a technical decision it’s a long-term investment in convenience, safety, and efficiency. Two of the most common types are MRL (Machine Room-Less) elevators and hydraulic Elevators. Both serve specific needs and come with their own sets of benefits and trade-offs. If you’re planning a new building or upgrading an existing one, understanding the pros and cons of each system is essential.

MRL Elevators: Compact, Modern, and Efficient

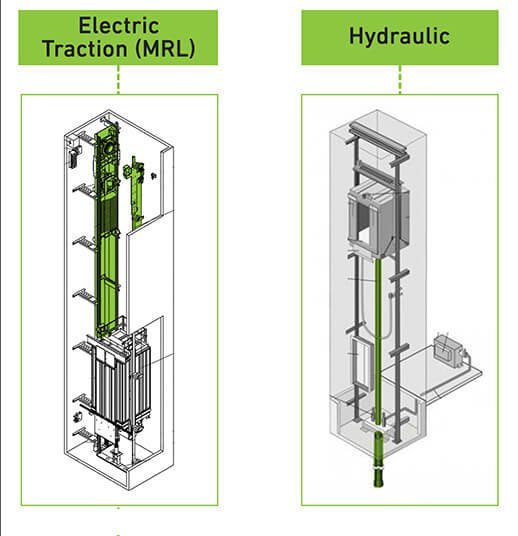

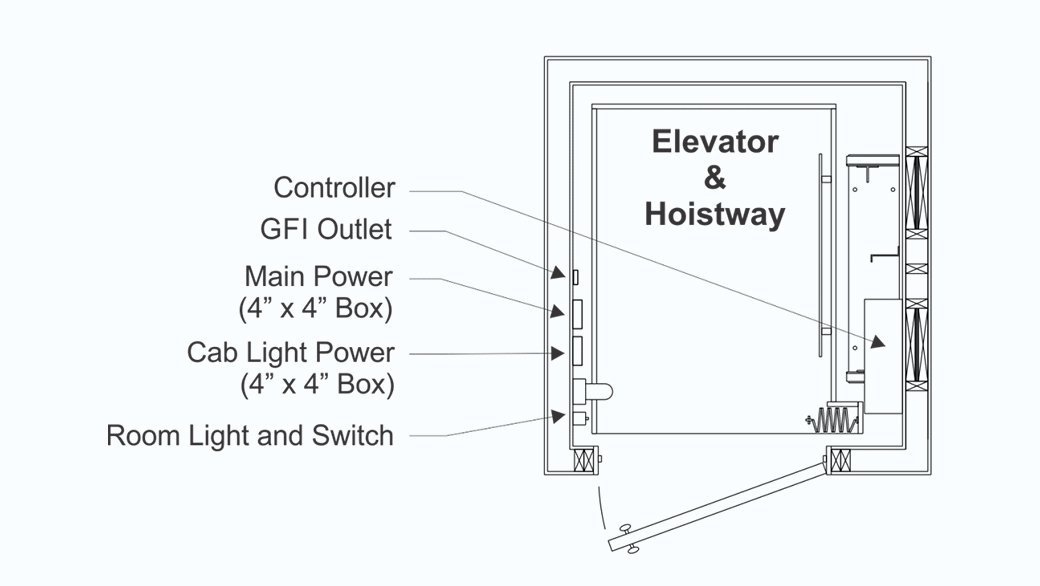

MRL elevators are a product of modern engineering. As the name suggests, these systems don’t require a separate machine room—a major space-saving advantage. All the mechanical equipment is housed within the hoistway itself, usually at the top or side of the shaft. This feature makes MRL elevators especially appealing in urban settings or in buildings where space is at a premium.

One of the biggest advantages of MRL elevators is their energy efficiency. They use gearless traction systems that consume less power and offer smoother, quieter operation. This not only enhances the passenger experience but also contributes to reduced operational costs over time. In terms of design, MRL elevators also allow for a cleaner building layout without needing to accommodate a bulky mechanical room.

However, MRL systems aren’t without their drawbacks. They generally have a higher upfront cost compared to hydraulic elevators. Their components are also more complex and may require specialized maintenance, meaning service technicians need to be properly trained and equipped. While they’re excellent for mid to high-rise buildings, the initial investment and complexity can be a deterrent for smaller projects.

Hydraulic Elevators: Reliable and Budget-Friendly for Low-Rise Buildings

Hydraulic elevators, on the other hand, have been a trusted solution for decades particularly for low-rise buildings (2 to 6 floors). These elevators work by pushing a piston up from below, powered by hydraulic fluid. This technology is straightforward, reliable, and less expensive to install than most traction-based systems.

One of the strongest advantages of hydraulic elevators is their affordability. The lower installation cost makes them a favorite for smaller residential buildings, clinics, and warehouses. They are also easier to maintain, thanks to their simple mechanical design. Most elevator technicians are well-versed in hydraulic systems, making servicing quick and cost-effective.

However, they do come with a few significant downsides. Hydraulic elevators are slower than MRL elevators and tend to consume more energy, especially during the upward journey. Over time, this can lead to higher electricity bills. Additionally, there is the potential risk of hydraulic oil leaks, which can pose environmental and safety concerns. These elevators also require a machine room to house the pump unit, which takes up additional floor space.

Choosing What’s Right for You

The decision between an MRL and hydraulic elevator comes down to your building’s height, usage, and budget. If you’re building upward and looking for efficiency and performance, MRL elevators are hard to beat. But if your project is low-rise and cost-sensitive, a hydraulic system may be the more practical option.

At Logolift, we specialize in helping builders, architects, and property owners choose the most effective elevator solution for their needs. Whether you’re interested in a space-saving MRL system or a proven hydraulic lift, our Finnish-engineered elevators are designed for performance, safety, and long-term reliability.

Making the right elevator choice isn’t just about moving people—it’s about moving forward with confidence.